Cutting heads overview

We can do both - fixed and rotation

Overview of different brackets

Pro bracket – rigid bracket, flexible use

The rigid intermediate bracket offers guaranteed protection for the customer investment with the same well-known performance. The hydraulic hoses are fed out to the back, in the centre of the extension arm protection. The hoses are exposed to less mechanical strain and therefore better protected during work with minimal visual contact.

Available for ER 650 – ER 2000

Dust suction hood

ER 50 with dust suction hood

For indoor use where water spraying is not possible, we also offer small drum cutter models with a dust suction hood for dry dust collection.

Available for ER 40 – ER 100

Water spraying system

ER 2000 with water spraying system

Our water spraying solution comes with a simple idea: to spray the water directly onto the cutting head area so the water is applied at the actual location itself.

Available for ER 40 – ER 5500

HATCON – A new level of control

ER 1500 with HATCON

HATCON enables next level fleet management by monitoring operating hours, location and service intervals of your tools.

Available for ER 100 –ER 5500

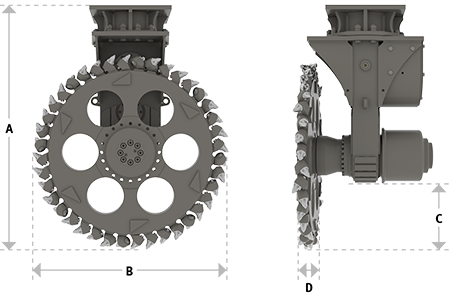

Cutting wheel

ER 2000 with cutting wheel

For narrow trenches and targeted slots in rock, concrete or asphalt.

Available for ER 50 – ER 3000

| Model | Cutting depth C ** | Cutting width D in mm | |||||

|---|---|---|---|---|---|---|---|

| 55 | 80 | 110 | 130 | 150 | 200 | ||

| ER 50 | 150 mm | ● | o | ||||

| ER 100 | 215 mm | ● | |||||

| ER 250 | 300 mm | ● | o | o | o | ||

| ER 600 | 300 mm | o | ● | o | o | ||

| ER 650 | 300 mm | ● | o | o | |||

| ER 1500 X | 500 mm | o | ● | o | o | ||

| ER 1500 XL | 560 mm | o | ● | o | o | ||

| ER 1700 | 560 mm | ● | o | o | |||

| ER 2000 | 560 mm | ● | o | o | |||

| ER 3000 | 560 mm | ● | o | o | |||

● = standard o = optional upon request ** = smaler cutting depth upon request

| |||||||

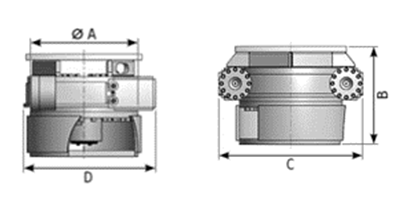

Erkat rotation units for the ER drum cutters

Rotation unit ERU 3

ERU Range |

| ERU 1 | ERU 2 | ERU 3 | ERU 4 | ERU 5 | ERU 6 | ERU 7 |

|---|---|---|---|---|---|---|---|---|

Carrier weight class 1 |

t |

2 - 5 |

3 - 8 |

8 - 15 |

15 - 25 |

20 - 40 |

30 - 50 |

50 - 70 |

Service weight 2 |

Kg |

200 |

250 |

510 |

970 |

1,150 |

1,250 |

2,400 |

Product weight |

Kg |

160 |

200 |

440 |

700 |

900 |

1,000 |

2,.000 |

A (diameter of gearbox) |

mm |

270 |

370 |

460 |

570 |

610 |

700 |

900 |

B (overall height of rotator) |

mm |

415 |

450 |

520 |

620 |

635 |

640 |

820 |

C (length) |

mm |

445 |

640 |

760 |

770 |

770 |

910 |

1.040 |

D (height) |

mm |

370 |

500 |

600 |

700 |

780 |

860 |

1170 |

Max. oil flow of rotary feedthrough |

l/min |

60 |

90 |

170 |

210 |

320 |

410 |

500 |

Max. hydr. pressure of rotary feedthrough |

bar |

350 |

350 |

350 |

350 |

350 |

350 |

350 |

Recom. oil flow of rotary drive |

l/min |

10 |

10 |

30 |

40 |

40 |

40 |

40 |

Recom. hydr. pressure for rotary drive |

bar |

160 |

160 |

160 |

160 |

160 |

160 |

160 |

Max holding torque of rotator drive |

Nm |

4,000 |

11,100 |

44,700 |

95,000 |

200,000 |

270,000 |

350,000 |

Number of rotary drive motors |

no |

1 |

1 |

2 |

2 |

2 |

2 |

2 |

Recommended for drum cutter |

type |

ER50 |

ER100 |

ER250, ER600 |

ER650 |

ER1500 |

ER1500, ER1700, ER2000 |

ER3000 |

¹ at 10 bar

| ||||||||